Traditional shear band fabrication entails spot welding of clamps to the shear band. Whereas with TOX-TECHNOLOGY heat created during the welding process actually burns the stainless steel. The composition of the stainless steel is attached and intercrystalline corrosion can result at the welding points.

The shear bands on Mission couplings incorporate the latest in stainless steel fastening techniques:

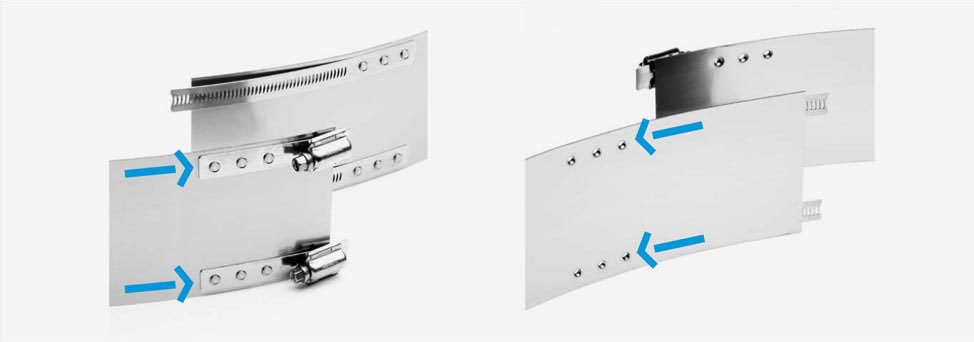

TOX-Technology (Clinching Process, no spot welds)

The negative aspects associated with spot welding are eliminated in this advance process, yet the bond meets or exceeds all relevant tensile strength and shear requirements.

| Properties | TOX-Point | Spot Weld |

|---|---|---|

| Corrosion | none | yes |

| Structural Change | none | yes |

| Dynamic Resistance | excellent | not perfect |

| Static Resistance | good | excellent |

| Energy Input | minimal | extremely high |

| Environment friendly manufacturing | excellent | bad (steams) |

SALT SPRAY TEST SHOWS DIFFERENT CORROSION RESISTANCES

In a salt spray test according to DIN 50 021 SS (neutral) the different corrosion resistances of spot welded and toxed connection were compared.

Test Certificate No. 22000197 MPA NRW

After only a few days a clear corrosion was visible on the spot welded test blocks.

The toxed (clinched) stainless steel bands did not show any corrosion after 504 hours (test ended after 3 weeks).